FAQ

Sediment and Carbon Filtration

Reverse Osmosis Filtration

IsoTwist Filters

Ultra Violet Sterilization

Ozone Sanitation

Toxic Information

IAMPO Certification

Sediment and Carbon Filtration

Sediment and Carbon filtration is the industry standard for specialized industrial and consumer water treatment application. Usually used together, each filter in this dual system has its own part to play in creating cleaner drinking water. Sediment filters are fairly straightforward, having one job, which is to remove particles (e.g. dust, dirt, rust) from the feed water. Activated carbon filters are the industry standard for specialized industrial and consumer water treatment applications. Activated carbon has been found to be extremely effective in reducing or removing organic chemicals, including chlorine, pesticides, industrial chemicals, THMs, PCBs and other similar halogenated organic compounds, as well as bad taste and odor.

Sediment Filter

Sediment filters come in many different dimensions (e.g. 2” X 10,” 4” X 10,” 2” X 20,” 4” X 20”) and micron gradients (e.g. 50 microns down to .5 microns). The job of a sediment filter is to remove suspended solids from the water according to its micron rating.

Granular Activated Carbon (GAC)

Granular Activated carbon is a form of charcoal that has been treated by high temperatures and steam in the absence of oxygen. This process produces small granules that are extremely porous with a high surface area. GAC filters remove organics from the water by holding them to its surface, a process known as adsorption. As water passes around each little particle of carbon, the organics adhere to the particles. One pound of granular activated carbon has a total surface area of about l25 acres (three football fields), giving each filter the ability to handle large amounts of water before becoming “used up.” When GAC is used in a tall column, most of the unwanted organic pollutants are absorbed in the top layers, and as the water passes downward it progressively contacts cleaner and cleaner carbon. This in-depth filtering “polishes” the water as it passes out of the column and provides a wide margin of organic removal.

While a wide variety of filters are made with GAC, not all will perform equally. Effectiveness varies with the kind of carbon used in the filter, the filter design, the way it is used and maintained, its age, and the condition of the water being treated.

Carbon Block Filters

Also referred to as Extruded Activated Carbon (EAC), this carbon filter is manufactured using a method of extrusion that allows the free formation of porous solids (in this case, carbon) in a highly uniform fashion. Because extruded activated carbon parts are produced on a single tool rather than on large numbers of individual molds, dimensional uniformity of each piece is exceptional. Uniformity, strength, porosity, permeability, sorbent capacity, and dimension accuracy are a few of the advantages to this technology.

Unlike the GAC carbon filter, where water flows around the carbon particles, the carbon block forces the water to penetrate through it. This allows for a more complete contact with and subsequent adsorption of chlorine, THMs, bad tastes and odors, toxic metals, and more.

The carbon block filter then becomes a reliable sediment filter as well. The pore size of the carbon block filter is variable, and is usually available in a range of l0 micron to sub-micron. When used in tandem, usually with a l0 micron first and a sub-micron second, these filters can provide the most complete removal of organic matter available. As with GAC filters, EAC filters do become “used up” as well, and should be replaced regularly.

Disadvantages

The only real drawback associated with carbon filters is that they can grow bacteria and harbor other (usually harmless) matter on the carbon surface. The risk is that over time this matter can break off and contaminate the water, defeating the whole purpose of water treatment. The carbon can also become “used up” as the adsorption of organic molecules saturates the media. Determining factors for the amount of time this takes are water temperature, sediment content, chlorine levels, organic chemical levels, and total amount of water treated.

Carbon filters will not remove dissolved solids, fluorides, heavy metals or mineral salts. If complete water purification is desired, the removal of these items can only be attained through reverse osmosis, deionization or distillation.

One of the drawbacks of a GAC filter is its tendency to “channel,” where water creates distinct paths through the media. This greatly reduces the available contact area, which shortens the effective life of the filter. It also means that additional prefiltering becomes necessary because the carbon is not at a uniform pore size for this purpose.

Filter Replacement

As mentioned, GAC and EAC cartridges should be replaced on a regular basis. Some determining factors for replacement time are water conditions and temperature, number of gallons treated, chlorine and other organic chemical content of the feed water, sediment and turbidity. For average household usage, depending on the size and type of the carbon filter combined with the family size and the factors listed above, expect to change out the filter every 6 to 12 months. For industrial and commercial use, every 2 weeks to 6 months, depending on application. The replacement cost of carbon block filters is usually higher than GAC filters. Prices will vary, as will quality, and the two don’t always go hand in hand. When you purchase a filter system, check with your dealer for the manufacturer’s recommendations.

When purchasing a filtration system, be sure that filters are replaceable and readily available, and the manufacturer/distributor is reputable (and will be around when you need filter replacements).

Reverse Osmosis Filtration

The reverse osmosis filtration process was originally developed more than 60 years ago as an affordable way to desalinate seawater. A properly designed reverse osmosis system adds a membrane to the Sediment and Carbon filtration system, resulting in an even purer drinking water, going from “filtered water,” as described above, to what the industry defines as “purified water.”

Reverse osmosis works by means of a semi-permeable membrane that looks like cling-film plastic wrap and is made out of the same sort of polymers. This membrane first filters out the tiniest molecules of practically all solid particles including bacteria, asbestos, microorganisms and organic material. This filter is so fine that its pores measure only two ten-millionths of an inch or 0.0005 microns and can barely be seen even under an excellent microscope. The same filter also removes toxic metals, mineral salts and other types of dissolved impurities by the process of reverse osmosis in which the impurities are repelled by the membrane’s surface while the purer water molecules are able to diffuse through it.

Reverse osmosis uses practically no energy other than the water pressure itself and is the only known process other than distillation that can separate pure water from molecules of:

- Sediment, turbidity, and particulate matter

- Dissolved solids

- Colloidal matter

- Radioactive elements

- Toxic metals

- Fluorine and fluoride

- Microorganisms

- Asbestos

- Herbicides and pesticides

- Heavier organic molecules (MW>300)

How Reverse Osmosis works inside the water filter

In a reverse osmosis filter, numerous sheets of the semi-permeable polymer membrane are wound in a spiral around a hollow tube that runs down the center. The pressure of the water as it enters the filter container forces the water molecules through the membrane into the hollow central tube leaving the impurities behind on the outside. This hollow central tube is connected to the outlet on your water dispenser, and it is this purified water that flows into your glass.

Meanwhile, the flow of the unfiltered water as it enters the container also forces the trapped impurities down and out of the filter by a separate drainage tube so that the membrane is being continually flushed clean when the filter is in use. It is this constant flushing action that gives the reverse osmosis membrane its longevity and prevents the build-up of accumulated impurities.

Reverse osmosis filters come in a range of sizes with diameters of 2-8 inches and lengths of 10-48 inches, depending on how much filtered water you need.

Types of Filters

The best type of membrane filter material for water supplied from wells and other non-chlorinated sources alike are made from thin film composite polyamides (TFCs) that are completely bacteria resistant. TFC membranes will deteriorate over time in the presence of chlorine and other oxidizing chemicals so carbon filters are always used before the TFC membrane to remove these oxidizing chemicals.

IsoTwist Filters

The easy twist-off disposable filter cartridges and RO membrane assembly are designed to make installation and replacement quick, easy, and sanitary. These are great for customers who like to do the filter replacement themselves.

Ultra Violet Sterilization

Ultra violet works to disinfect water because light rays with wavelengths of 240-280 nanometers destroy 99.9% of the crucial DNA of viruses and bacteria that prevents them from reproducing.

It is an excellent natural means to purify water without resorting to harsh or toxic chemicals and works to eradicate even Giardia and Cryptosporidium parasites that are often very resistant to chemical disinfection. Clearing your water of these types of drug-resistant water-borne parasites is particular important for young children, seniors, and anyone whose immune system is compromised in any way who may be more susceptible to the type of illnesses they can cause.

Ultra violet sanitization is also a good way of disinfecting well water and other water sources that do not contain chlorine or other cleansing chemicals.

Ultra violet water disinfection does not remove potentially beneficial minerals, or change the odor or taste of the water in any way, and if installed early in your system can help to prolong the life of other types of filters by reducing the need to clean and flush your system so often.

How the Ultra Violet System Works

An ultra violet bulb contained in a watertight stainless steel tube burns constantly, irradiating the water with its purple light. Water flow is reduced to just 0.5 GPM that allows time for the ultraviolet disinfection process to take effect. The ultra violet bulbs are designed to give 9,000 hours of continuous use, which in practice means you will need to change it about once a year. When the bulb does burn out, an alarm sounds to alert you to change it.

Ozone Sanitation

How Ozone Disinfects the Filtered Water in your Bottleless Cooler

Ozone is a naturally occurring disinfectant that is composed of three oxygen molecules. It is, in fact, a naturally occurring, colorless gas that is formed in the uppermost levels of the atmosphere when oxygen molecules are struck by ultra violet light and divided into individual O1 atoms. When three of these individual atoms combine temporarily, O3, otherwise known as ozone, is the result. Ozone is also created in lower atmospheric levels during electric storms and is the source of that clean, fresh smell that only perfumes the air after an electric storm has occurred.

Ozone is actually a very unstable gas that is quick to form and quick to dissipate – once it is produced, ozone has a half-life of just 10-20 minutes in ambient (normal) conditions, which means it has to be electrically generated at the time disinfection is required, since it cannot be stored for later use.

Ozone disinfects by being very quick to give up an oxygen atom when it comes into contact with organic matter causing the other two atoms to revert to their original O2 (oxygen) status. If ozone is introduced into water it quickly reacts with any viruses, mold spores, and the membranes of any microbes present in solution, disrupting their DNA and RNA structures, causing them to oxidize and kills them in the process.

Ozone also attacks microbial bio-film, causing it to biodegrade in much the same way as it does with polysaccharides. The great advantage of introducing ozone to water is that it does not leave any noxious chemical residues (the only residue is oxygen itself).

Advantages of Ozone

- Powerful and rapid oxidizer that is one and half times more efficient than chlorine and effectively destroys a wider range of toxins

- Germs, viruses and other noxious organic matter are killed in a matter of seconds.

- Odorless

- Tasteless

- Oxygenates water after disinfection

- Zero chemical residues (only oxygen is released!)

- Does not need special mixing or handling considerations

- With ozone disinfection, your bottleless water cooler will only need to be occasionally cleaned

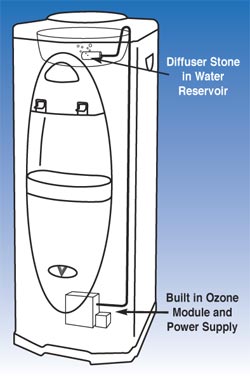

Ozone Disinfection in Practice

Ozone disinfection is the final step in your bottleless office or home water filtering and purification processes. A small ozone generator is attached to the outside of your bottle-free water cooler and dispenser. This generates tiny ozone bubbles into the water cooler reservoir which instantly get to work oxidizing and killing all microbes, bacteria, viruses, molds and other organic matter. The only chemical residue as a result of the oxidation process is oxygen gas itself, which is released back into the atmosphere. This means that the Ozone Sanitizer only needs to be cleaned out occasionally and far less than with other bottleless water disinfection methods.

Ozone sanitation does not affect either the taste or odor of the water.

Toxic Information

It is a sad reality that in many areas, our nation’s potable water hygiene fails to meet the standards stipulated by our public health authorities. In many areas of the USA, the water that we use to drink is actually heavily polluted with nickel, lead, and other types of heavy metals, which can cause allergic skin reactions and eat away tooth enamel.

In some areas, the tap water actually contains such high concentrations of toxic arsenic, manganese, and barium that it may even contribute to high incidences of nervous system and kidney damage and even cancer and birth defects among the consuming population.

Despite the introduction of the Clean Water Act more than 40 years ago, a recent study by the New York Times showed that more and more industries are not doing all they can to prevent toxic chemical residues seeping into our potable water supply – with devastatingly toxic results.

In the last five years alone, there have been more than half a million violations nationwide of the Clean Water Act, and states seem to be reluctant or unwilling to impose the necessary fines and penalties to deter the increase in industrial offenders.

In addition, almost 20 million Americans fall victim each year to waterborne pathogens such as bacteria, parasites and viruses, which they inadvertently consume in inadequately treated tap water.

Almost 40% of community water systems violate the Clean Health Act each year, often due to seepage of animal and other organic wastes, agricultural pesticides, and other chemicals that filter into the water supply. This translates into an incredible 23+ million people actually consuming water that could pose potentially devastating problems to their health.

Aren’t these good enough reasons in themselves to invest in an in-house bottleless water filtration, purification, and cooling system in your home or place of work?

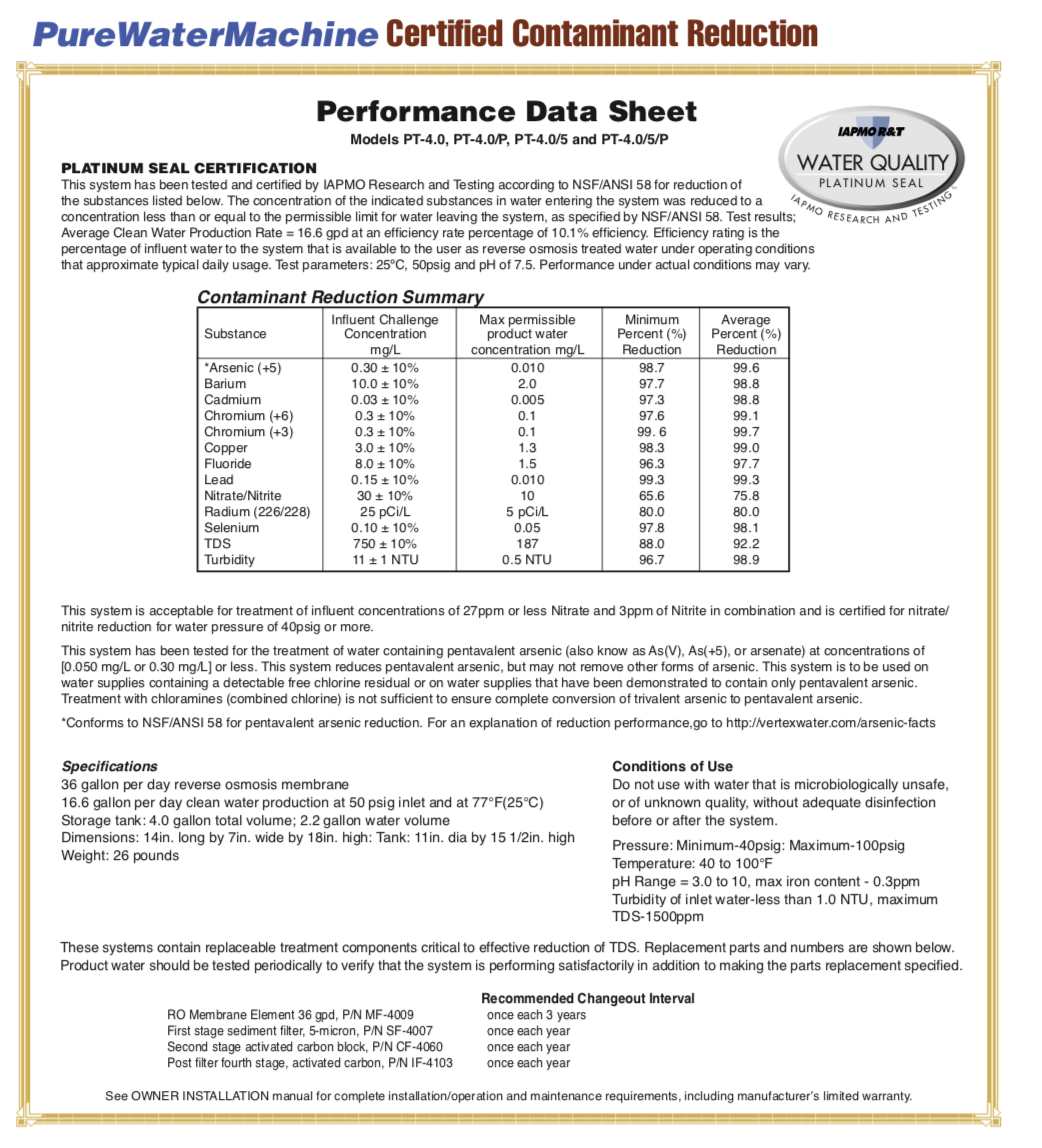

IAMPO Certification